YOUR BOUTIQUE FOR hi-tech APIs

YOUR BOUTIQUE FOR hi-tech APIs

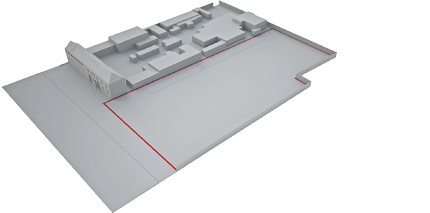

The Partner of choice for chemical-pharmaceutical manufacturing.

ICROM is an API CDMO specialized in development and GMP manufacturing of Active Ingredients.

With over 50 years of experience, ICROM is the partner of choice for pharmaceutical outsourcing, able to provide a wide range of tailored services, custom development and custom manufacturing of NCEs, generic APIs.

Leveraging sophisticated know-how, we build high-tech solutions to create complex molecules.

Everything we do for our Customers is driven by a deep passion and the firm belief that Public Health needs high expertise, high quality products as well as tailor made, fast and reliable solutions.

With over 50 years of experience, ICROM is the partner of choice for pharmaceutical outsourcing, able to provide a wide range of tailored services, custom development and custom manufacturing of NCEs, generic APIs.

Leveraging sophisticated know-how, we build high-tech solutions to create complex molecules.

Everything we do for our Customers is driven by a deep passion and the firm belief that Public Health needs high expertise, high quality products as well as tailor made, fast and reliable solutions.